Material info

Aluminium-manganese the more stable solution

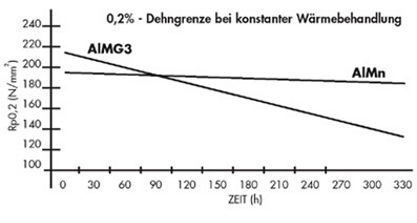

The true stability of a baking tray only comes to light during actual baking. Having to withstand long-term use in the oven and temperatures of around 230 °C, AlMn proves to be the more dimensionally stable alternative to the AlMg 3 alloy, wich was previously used. As shown in the graph, AlMg 3 has a slightly higher stability when not exposed to heat, however, this stability decreases with every baking and after a short time is significantly lower than the stability of AlMn. This is key advantage of aluminium-manganese (AlMn).

Aluminium-Manganese is more heat resistant

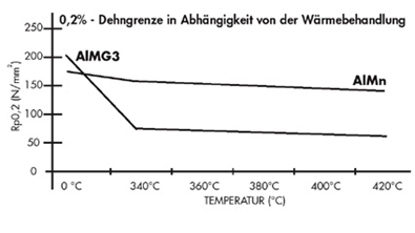

When perforated trays under go non-stick coating process, the coating is fired at about 420 °C. The graph based on a study by the institute of Ferrous Metallurgy at the RWTH Aachen, shows clearly, that AlMg 3 after only one single heating at 340 °C loses almost half of ist original stability and ‚anneals‘, while the AlMn curve practically remains constant and the material almost nearly retains ist original stability.